Ballwinders Subdomain

Main menu:

- Overview

- Typical Uses

- Operation

-

Support

- Maintenance

- Support (help line)

- Ball Winder Manual

- Tech Alerts!

- Options

- Store

- Misc Items

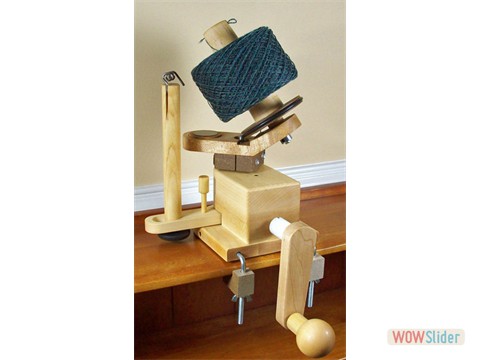

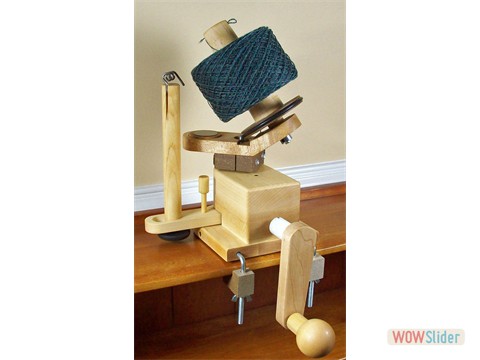

Nancy's Knit Knacks manufactures the World's

leading commercial quality ball winder. Although NKK was not the first

company to design a ball winder, it was the first to design a heavy duty

unit made from wood that could be used both manually and electrically.

Shipments of the manual crank model started in the Fall of 2006. The

motorized unit started shipping 2 years later in 2008. Customers who had

purchased the manual unit could then upgrade their system by simply

adding the "Power Base" to their setup. An industry first.

As of the summer of 2015, approximately 7,000 ball winders have been shipped. Although the first ball winder looks very similar to the most recently shipped unit, there have been many subtle refinements made to the unit over the years. It is because of these refinements that the unit continues to attract professional and commercial customers year after year.

This website provides detailed information about the ball winder. We hope that every question that you might have will be answered within the pages of this site. But if they aren't, we encourage you to drop us a note or give us a call and we will get back to you very quickly.

Our ball winders are made by hand. We utilize a number of commercial wood and metal processors as well as private craftsmen to manufacture the components used in these units. We then complete any final assembly operations, test and package the final products at NKK in North Carolina.

We make 12-16 units every week. In fact, we have done this since the Fall of 2006 (for almost 7 years running). The only kind of products that have that rate of steady production are popular staple food items like ketchup! It is extremely rare that we have any left at the end of the week that have not shipped.

If you purchase one of our ball winders, it will be the last ball winder that you ever need to buy. Just be sure to follow our maintenance instructions and you will not be disappointed. We promise.

As of the summer of 2015, approximately 7,000 ball winders have been shipped. Although the first ball winder looks very similar to the most recently shipped unit, there have been many subtle refinements made to the unit over the years. It is because of these refinements that the unit continues to attract professional and commercial customers year after year.

This website provides detailed information about the ball winder. We hope that every question that you might have will be answered within the pages of this site. But if they aren't, we encourage you to drop us a note or give us a call and we will get back to you very quickly.

Our ball winders are made by hand. We utilize a number of commercial wood and metal processors as well as private craftsmen to manufacture the components used in these units. We then complete any final assembly operations, test and package the final products at NKK in North Carolina.

We make 12-16 units every week. In fact, we have done this since the Fall of 2006 (for almost 7 years running). The only kind of products that have that rate of steady production are popular staple food items like ketchup! It is extremely rare that we have any left at the end of the week that have not shipped.

If you purchase one of our ball winders, it will be the last ball winder that you ever need to buy. Just be sure to follow our maintenance instructions and you will not be disappointed. We promise.

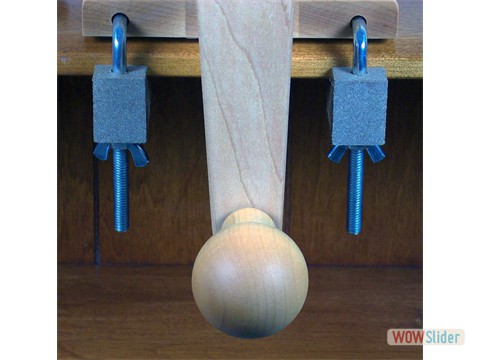

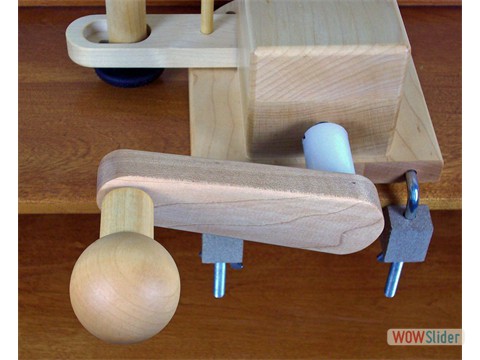

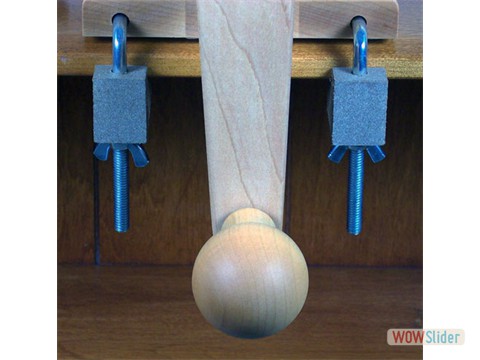

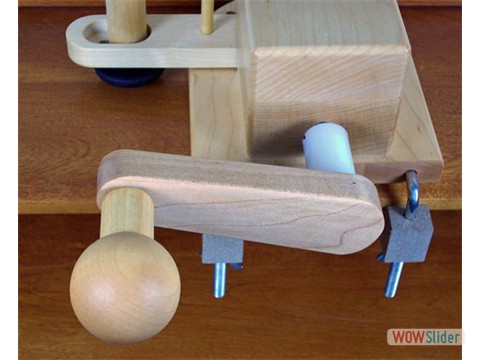

The HDBW is made from Maple hardwood. It also incorporates super strong steel shafts which measure 5/16", 3/8" and 10mm in diameter. This rigid structure assures the user of many years of reliable operation.

The maintenance section provides information on maintainng your ball winder. Periodically cleaning the internal gears of fiber build-up is the main maintenance item and is easy to do.

This Website

Please review the various webpages on this website.

Learn about the options that are available.

- Check the maintenance section out. This also includes key adjustments that you will be required to make over the life of the unit.

We also sell a line of Yarn Ball Cores which are used to put your yarn onto after winding a ball.

Check them out here

Yarn Ball Cores

Mini-Cores